Anyone working with complex industrial plants knows how crucial it is to have reliable systems to manage machinery, flows, and process variables. Modern industrial automation relies on these mechanisms, which allow entire plants to operate continuously, safely, and efficiently.

Among the technologies that make this possible ICS, Industrial Control Systems, alongside SCADA systems have taken on a central role. These are not just technologies, but strategic tools that affect how companies operate, make decisions, and respond to unforeseen events.

Moreover, for those involved in industrial plant design, using tools like ESAPRO makes a difference: a complete suite that supports process modeling, piping, and electrical plant design, integrating advanced functions with an interface designed to adapt to any project scale, from a single production department to large infrastructures.

Sectors such as energy, manufacturing, water treatment, or transportation have now integrated these systems into their processes, relying on automatic control networks and supervision platforms to keep everything under control in real time.

This article clarifies the meaning of Industrial Control System, how it works, and what distinguishes it from SCADA. Understanding its logic is not just a theoretical exercise, but a necessary step for those who want to design, optimize, or simply understand today’s industrial infrastructures.

What is an Industrial Control System

The term Industrial Control System (ICS) refers to the set of hardware devices, software, and network components used to monitor and manage industrial plants. It is a broad category that includes various types of architectures and technologies, applied both in compact systems and large-scale infrastructures.

The core of an ICS is automation: it enables continuous control of machinery, flows, and parameters, reducing the need for direct human intervention. This applies not only to production lines but also to energy plants, water treatment, transportation management, and many other strategic applications.

Depending on the complexity of the process and the operational context, an industrial control system may include elements such as PLCs (Programmable Logic Controllers), DCS (Distributed Control Systems), RTUs (Remote Terminal Units), sensors, operator interfaces, central servers, and supervisory software. Each of these components has a specific function in data collection, signal analysis, and operational response activation.

Over time, the separation between IT (Information Technology) and OT (Operational Technology) has narrowed. Today, many ICS are networked and communicate with broader information systems, opening new possibilities for remote control and centralized management.

This convergence offers real benefits: greater visibility into performance, predictive capabilities, and process optimization. At the same time, however, it introduces new challenges, especially in terms of security. Systems once isolated are now exposed to cyber threats that, if unmanaged, can jeopardize operational continuity.

For this reason, knowing the structure and functioning of ICS is not only useful for those who design or develop industrial plants, but has become a key point for anyone working with critical infrastructures.

How does an Industrial Control System (ICS) work

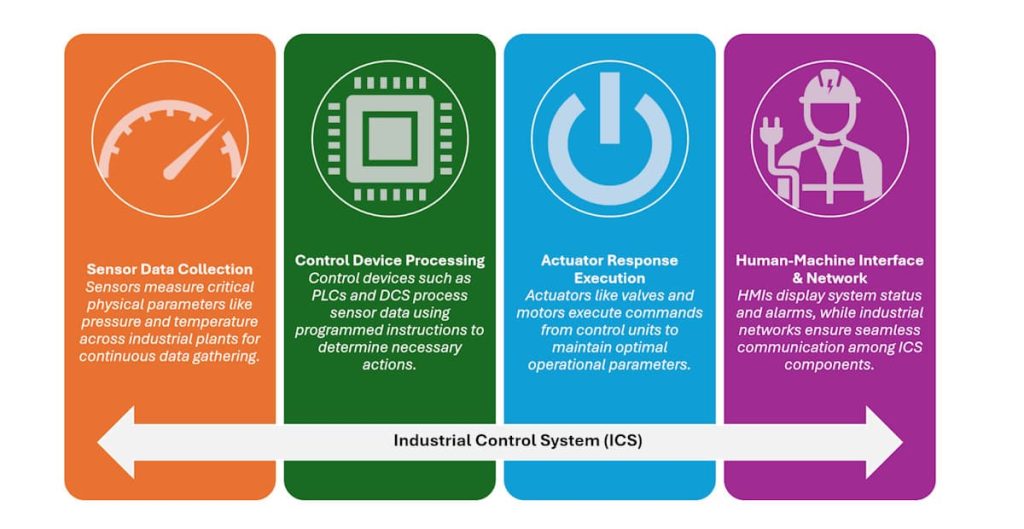

The operation of an ICS is based on a well-defined chain of detection, processing, and action. It all starts with sensors placed on the plants, which measure physical variables such as pressure, temperature, level, or speed. These signals are sent to control devices, PLCs or DCS, which interpret them according to preconfigured instructions.

Once the data is analyzed, the system decides on the response to be implemented. PLCs or DCS send commands to actuators, which can be valves, motors, pumps, or other mechanical devices. In this way, the ICS control systems regulates the plant’s operation in real time, keeping operating conditions within desired parameters. This cycle repeats continuously and autonomously, ensuring stability, precision, and responsiveness.

Everything is coordinated through an industrial network connecting various components. To support operators, the industrial automation and control system also includes Human-Machine Interfaces (HMI), control panels that display system status, record alarms, and allow manual intervention when necessary. Integration with other systems, such as SCADA or management software, finally enables analysis of collected data on a larger scale and strategic decision-making based on updated information.

Differences between Industrial Control System and SCADA

ICS and SCADA systems are two fundamental components in industrial automation, but they meet different needs. The former directly manages the control of physical processes, while the latter handles supervision, collects data, and enables centralized interaction with multiple plants.

To truly understand how they relate and what distinguishes them, it’s useful to look at several key areas.

- Operational function

ICS control systems automate processes and ensure continuous control of industrial plants, such as in manufacturing and chemical processing. They are designed to perform physical actions, regulate parameters, and start or stop machinery. SCADA, on the other hand, collects and centralizes information from the field, making it readable and manageable by operators and management systems. In practice, while ICS “does,” SCADA “sees and shows.”

- Architecture and components

An ICS includes field devices such as sensors and actuators, controllers (PLC controller, DCS) that process signals and commands, and local HMIs for operators. The SCADA system, instead, is structured around a central station that communicates with remote units (RTU, PLC) distributed across the territory, using a network to collect data and send commands. Control in SCADA systems is less tied to the physical site and more oriented toward an overall view.

- Application context

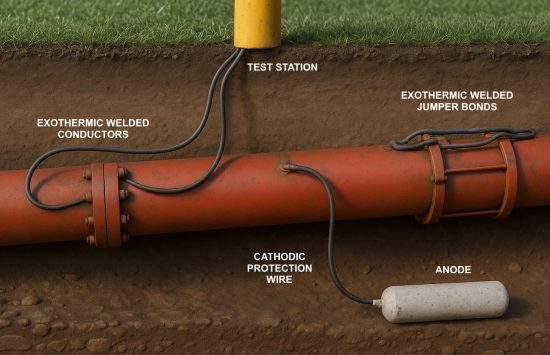

ICS is used in contexts requiring constant operations and immediate responsiveness, such as manufacturing, chemicals, or energy generation. SCADA is used where remote supervision of distributed systems is needed, for example in industrial water treatment plants, electrical distribution plants, or gas pipelines, where the distance between control points is a critical factor.

- Cybersecurity

From a security perspective, ICS control systems tends to operate on more isolated and controlled networks, but often includes outdated technologies not designed with native protection criteria. SCADA, by its nature, is exposed to greater risks because it communicates with many remote devices over more open networks. Data protection in transit and device authentication are therefore central aspects of its management

- Management and maintenance

The distributed architecture of Industrial automation and control system offers greater resilience and the ability to contain faults, but can be more complex to manage in case of updates or coordinated interventions. SCADA, instead, centralizes control, simplifying maintenance, but also introduces unique critical points: if the master station is compromised, the entire system can become ineffective.

ICS control systems and SCADA are not competitors but respond to different logics within the same infrastructure. The former ensures that the industrial process works reliably and autonomously. The latter provides vision, remote access, and the ability to intervene from a centralized point. Knowing how to distinguish them means knowing how to integrate them correctly, to achieve a plant that works better, reacts faster, and defends itself more effectively.