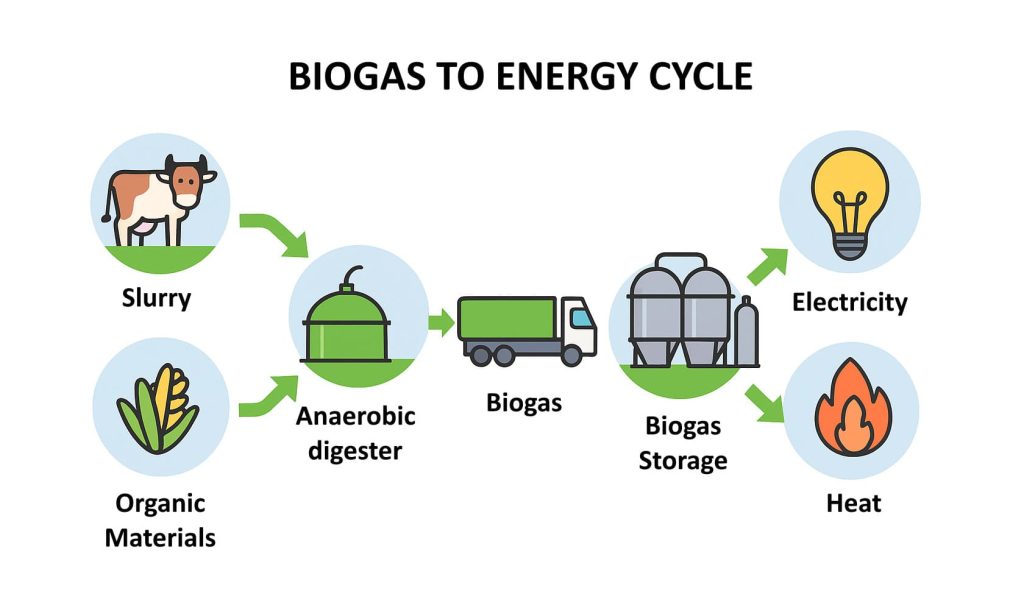

Biogas plants are industrial systems designed to convert organic material into energy using natural biological processes. They are based on a simple and well-established principle: the anaerobic fermentation (in the absence of oxygen) of substances of plant or animal origin to produce a gas mixture rich in methane, which can be used to generate heat or electricity.

To fully understand this technology, it is useful to clarify some key definitions.

Biomass is the organic material, derived from crops, livestock waste, or agro-industrial residues, that serves as the raw material for the process.

Biogas is the result of fermentation, a mixture mainly composed of methane and carbon dioxide, with a variable percentage of other minor gases. These two elements — biomass and biogas — are the cornerstones on which the entire plant is based.

Choosing a biogas plant means enhancing already available organic resources, reducing dependence on fossil fuels, and lowering net carbon dioxide emissions. From this perspective, the design of a biogas plant is not only a technical matter but also a strategic one for sustainable resource management and environmental impact mitigation.

For those involved in the design and management of this type of plant, digital tools also play a fundamental role in ensuring efficiency and precision. A P&ID software like ESAPRO, for example, allows the creation of intelligent process diagrams guided by piping specifications, reducing errors and improving consistency between documentation and the 3D model. Features such as an integrated database, automatic generation of material lists, and BIM compatibility make it a reliable solution for complex projects, such as the design of a biogas plant.

In the following paragraphs, we will see how biogas plants are made and analyze their functioning in detail.

How biogas plant is made

Biogas plants are designed to adapt to different production contexts, from intensive agriculture to specific industrial sectors that generate large quantities of organic residues, such as food, dairy, or paper industries.

Most biogas plants in operation today are medium to large in size, to ensure sufficient production volumes and adequate economic returns. Domestic use remains rare, mainly due to the lack of clear regulations and the complexity of management on a small scale.

From a technical point of view, a biogas plant consists of three main systems.

- Anaerobic Digester. The heart of the plant consists of one or more digesters, large, closed tanks where the biomass undergoes the anaerobic fermentation process. The technological configuration of the digesters varies depending on the type of material treated. The two most common modes are wet digestion, where the percentage of dry matter in the digester is maintained around 10%, and dry digestion, suitable for denser substrates, with a dry matter content starting from 30%.

- Cogeneration System. Downstream of the digester is the cogeneration system, which uses the produced biogas to generate energy. An internal combustion engine transforms the gas into mechanical energy, which is then converted into electricity through an alternator. At the same time, the residual heat from the exhaust gases and the engine cooling water is recovered through heat exchangers and can be reused in the form of hot water, steam, or thermal fluid for industrial or civil uses.

- Biogas Upgrading System. Finally, some plants have a biogas upgrading system, which purifies it, transforming it into biomethane. This refining phase is essential when the gas is to be injected into the distribution network or used as fuel. Among the available technologies, one of the most widespread is the membrane system, capable of selectively separating methane and carbon dioxide thanks to the different permeability of the two gases.

These three elements — digestion, cogeneration, and upgrading — define the essential structure of a modern biogas plant and explain its application versatility.

How a biogas plant works

The operation of a biogas plant is based on a natural biological process that the plant recreates and controls on an industrial scale. It all starts with the collection of biomasses, that is, the organic material destined for fermentation: agricultural residues, livestock effluents, agro-industrial waste, or the organic fraction of urban waste. These materials are prepared and stored in special tanks to ensure homogeneity and adequate quality for feeding the digesters.

Inside the digesters, anaerobic digestion takes place. The biomass, in an oxygen-free environment, is decomposed thanks to the combined action of bacteria and enzymes that release gas and heat. This reaction produces a gas mixture composed mainly of methane and carbon dioxide, along with small amounts of other gases such as nitrogen, hydrogen, and sulfur compounds.

At the same time, the residual solid and liquid part, called digestate, is separated from the gas and can be used as a natural fertilizer.

The biogas thus produced is sent to the cogeneration system to be converted into electricity and heat, or, in plants equipped with an upgrading section, it is purified to obtain biomethane. Biomethane, equivalent to fossil methane in purity and performance, can be injected into the network, used as fuel, or for heating.

This sequence — from the collection of biomass, to its treatment in the digesters, to the valorization of biogas — defines a virtuous cycle capable of generating renewable energy by exploiting materials otherwise destined for disposal, with tangible economic and environmental benefits.