Industrial pipe welding represents an essential process in the creation of metal structures, plants, and components intended for strategic sectors such as energy, chemical, and manufacturing. The evolution of industrial welding technologies has led to the development of increasingly precise and efficient methods, suitable for meeting specific design needs.

Techniques such as TIG welding and MIG welding are among the most used today to ensure strong, reliable joints that meet the required quality standards. Among the most important applications is pipe welding, used to join metal pipes in industrial plants, refineries, and power plants.

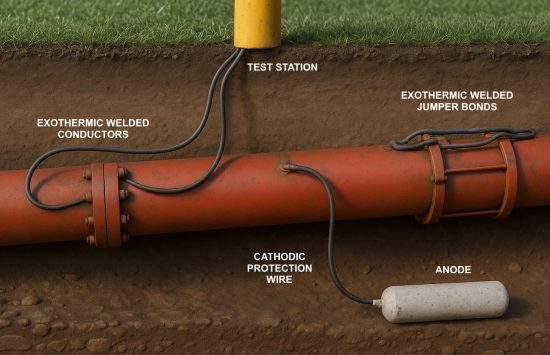

Pipe welding techniques are fundamental to ensuring the integrity of piping networks, both in the construction of new infrastructures and in the maintenance of existing ones, always in compliance with industry regulations and standards. This application is often distinguished from pipeline welding, used on pipelines intended for long-distance fluid transport, such as water or oil.

In this in-depth analysis, we will explore the main types of welding used in the industry, focusing on the distinctive characteristics of each method and the software tools that support their design.

Main types of industrial welding

Industrial welding includes a set of techniques used to create strong and safe connections between metal components in various production sectors. Each method is distinguished by specific operating modes, treatable materials, and technological requirements and is selected based on project needs, production volumes, and the required quality of the joints.

Among the most used technologies are TIG welding, MIG, and MAG welding, as well as less common but equally important processes. Knowing the characteristics of each method is essential to choose the most suitable solution during the design and construction of plants.

To optimize the industrial plant design process and generate automatic isometric sketches, advanced tools like ESAPRO Isometrics allow you to easily customize the position of dimensions and symbols, adding manual notes directly to the drawing. Additionally, it is possible to generate welding tables, material lists, and pipe cutting lists, thus optimizing the entire workflow and ensuring precise and efficient design.

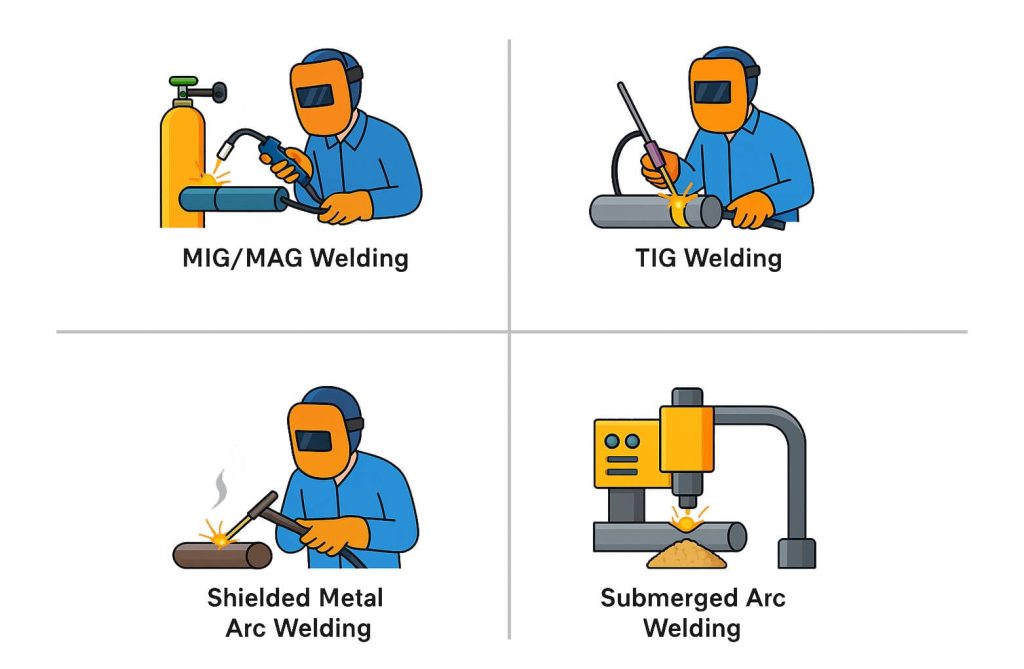

The main types of industrial welding are:

- MIG and MAG Welding (Metal Inert Gas / Metal Active Gas)

This process uses a continuous electrode wire fed through a torch and protected by an inert or active gas. It is one of the fastest and most efficient techniques, ideal for working with materials such as carbon steel, stainless steel, and aluminum. MIG and MAG welding is particularly suitable for high-volume applications, such as automotive production and the construction of complex metal structures. The ease of automating the process makes it perfect for industrial environments where productivity is a determining factor. - TIG Welding (Tungsten Inert Gas)

TIG welding uses a non-consumable tungsten electrode and protective gases such as argon or helium. It is appreciated for its precision, capable of producing clean joints without visible defects. This method offers superior control of the molten pool and is ideal for sensitive piping materials such as aluminum and light alloys. It is chosen especially when a perfect joint aesthetic and high strength are required, for example in the construction of complex industrial plants or components intended for the aerospace and pharmaceutical sectors. - Shielded Metal Arc Welding (MMA – Manual Metal Arc)

Among the most traditional processes, MMA welding uses coated electrodes that provide both the filler material and the protection of the weld pool during the process. It is an extremely versatile technique, suitable for working in difficult environments without the need for external gases. Thanks to its simplicity and robustness, it is widely used in the maintenance of industrial plants, mechanical workshops, and the construction of steel structures in non-optimal conditions. - Submerged Arc Welding (SAW – Submerged Arc Welding)

Submerged arc welding is an automated process that ensures complete protection of the weld pool through the use of granular flux. This method allows for high penetration connections on thick joints, with very high productivity. It is the ideal choice for the construction of tanks, large-diameter industrial pipes, and heavy steel structures, where it is necessary to reduce processing times while maintaining high-quality standards.

The choice of technology depends on various factors, including the type of material to be worked, the thickness of the metal, the required precision specifications, and the available budget. It is essential to carefully evaluate these aspects to ensure not only the efficiency and quality of the work but also to optimize the overall project costs. Using the right technology for each application helps achieve safe and strong joints, essential for the durability and efficiency of any industrial plant.