The Industrial Internet of Things (IIoT) is a key evolution in how companies collect, analyze, and use data from plants, machinery, and production processes.

At the heart of IIoT are sensors, actuators, and intelligent systems capable of transmitting real-time data, generating insights that enhance control, efficiency, and responsiveness in industrial facilities.

It is not just about factory-installed devices: the Industrial IoT involves a complex and connected network that can include advanced robotics, Supervisory Control and Data Acquisition (SCADA) systems, cloud platforms, artificial intelligence and predictive analytics.

This architecture, which is a key component of Industry 4.0, is not limited to the manufacturing sector, but extends to areas such as agritech, logistics, energy, and even healthcare and retail, confirming how it now has a cross-cutting impact on different production and decision-making ecosystems.

What is the Industrial Internet of Things (IIoT)?

Industrial Internet of Things refers to a structured network of interconnected devices integrated with applications specific to industrial environments. This smart system allows companies to acquire, exchange, and analyze large volumes of data from plants, production lines, and supply chains. Real-time data enables faster, more reliable, and efficiency-oriented operational decisions.

The industrial IIoT infrastructure extends beyond the plant itself to the entire production ecosystem, including suppliers and customers. This openness supports just-in-time supply, order tracking, and progress monitoring enabling a continuous, transparent flow of information and smoother management.

The market related to the Industrial Internet of Things is booming and includes a variety of key technologies. These include cloud and edge computing solutions, which are essential for the decentralized collection and processing of Big Data in industrial plants, but also advanced robotics, artificial intelligence, machine learning, machine-to-machine (M2M) systems, big data analytics, cognitive computing, mobile technology and, of course, the sensors and connected devices typical of industrial IoT.

Together, these technologies improve plant performance and reduce waste and inefficiencies. Benefits include continuous monitoring of operating conditions, predictive maintenance, optimized logistics, and enhanced cybersecurity and physical safety.

The goal of IIoT is thus to transform factories into smart and adaptive environments so that every element from the individual component to the production system is able to talk and act based on the data received, thus redefining the paradigms of industrial efficiency.

Difference between IIoT and IoT

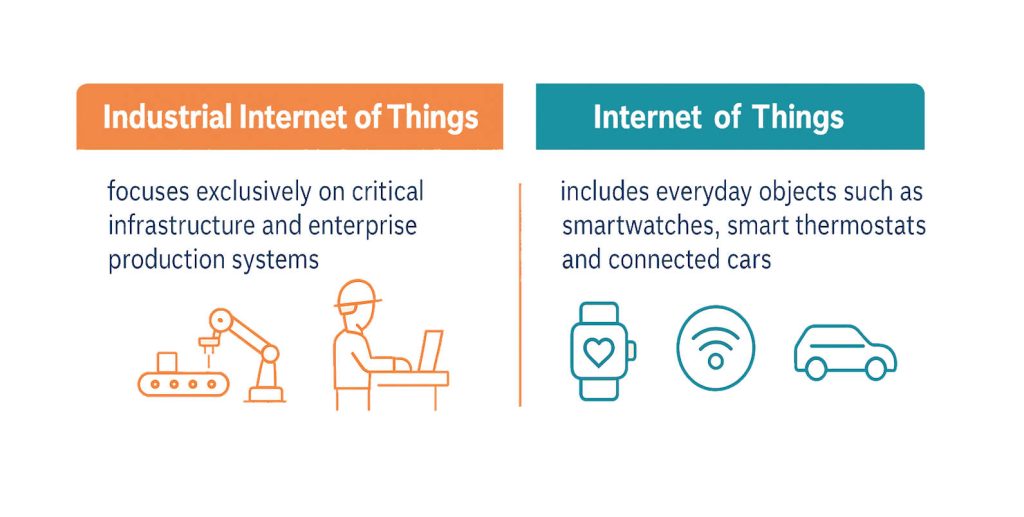

There is often confusion between IoT and IIoT. Understanding the difference between IoT and IIoT is critical to realize the true potential of both.

The Industrial Internet of Things (IIoT) focuses exclusively on critical infrastructure and enterprise production systems, thus distinguishing itself from the more consumer-oriented IoT, which includes everyday objects such as smartwatches, smart thermostats and connected cars.

In industrial settings, however, the flow of data is much more intense, continuous and sensitive, requiring solutions designed to ensure security, resilience and interoperability. That’s why IIoT is increasingly discussed in terms of integrated, scalable platforms capable of managing complex workloads in error-intolerant environments.

Main applications of the Industrial Internet of Things

As anticipated, the Industrial Internet of Things (IIoT) is not just a technology, but a set of solutions capable of radically transforming industrial processes, increasing efficiency, safety and responsiveness. Its strength lies in integrating smart devices and software platforms to create continuous data flow among machines, systems, and operators.

Thanks to advanced connectivity and real-time analytics, industrial IoT makes it possible to optimize every stage of the production cycle, from manufacturing to logistics to product lifecycle management.

To support this transformation, advanced tools are needed to accurately represent production plants in every detail. ESAin’s industrial design software meets this need by offering powerful functions to create complete, detailed 3D layouts.

With tools for automatic line routing, guided insertion of piping and components, ESAin applications make it possible to speed up design while maintaining a high level of accuracy and consistency with the logic specific to the industrial internet of things.

So, what are the most common IIoT applications? Let’s explore them.

- Smart Factory

IIoT enables real-time production tracking, improved workplace safety, predictive maintenance, and simplified material handling. Sensors on production lines collect continuous data on machine status, enabling targeted actions and dramatically reducing downtime.

- Smart Logistics

The Industrial Internet of Things applied to logistics makes it possible to continuously track goods using sensors and Radio-Frequency Identification (RFId) technologies. This results in more efficient management, precise control of transportation fleets (through, for example, the use of GPS systems), and increased safety in complex logistics centers. IIoT platforms also provide constant updates on the status of shipments and warehouses.

- Product life cycle (Smart Lifecycle)

Data collected from products provide valuable information to improve future versions, better manage the end-of-life phase, and make collaboration with suppliers more effective in the design stages. IIot in this case translates into a strategic tool to continuously innovate their products.

But the potential of Industrial IoT does not stop there. Beyond manufacturing contexts, its applications extend to strategic areas such as supply chain management, where sensors and connected platforms enable precise inventory control, fixed asset reduction and dynamic supply planning.

In the retail world, it makes it possible to analyze consumer behavior in real time, optimize the arrangement of products on the shelves and customize promotions based on the data collected. Intelligent building management also benefits from the integration of connected devices, capable of regulating energy consumption, monitoring room access and preventing technical failures.

Thus, the industrial internet of things is a flexible ecosystem that can adapt to very different operational needs, improving not only productivity but also sustainability, safety and the overall quality of industrial operations