When it comes to industrial innovation, having a promising idea is not enough: it is necessary to understand how ready that technology truly is for use in a real-world context. The TRL scale, acronym for Technology Readiness Level, was created exactly for this purpose. It is a structured method for measuring the degree of technical maturity of an innovation, developed by NASA in the 1970s to manage risks in its space programs and now adopted in numerous sectors, from aerospace to energy, and even industrial infrastructure.

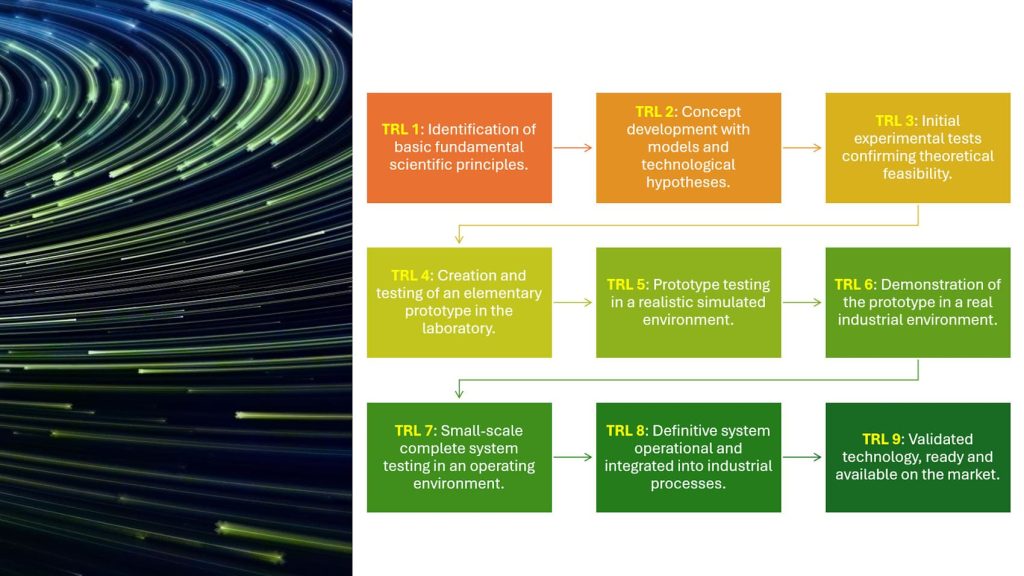

The TRL scale consists of nine progressive and well-defined levels, ranging from the observation of a basic principle to the use of a complete system in real operating conditions. Each intermediate step corresponds to a concrete stage of development: laboratory demonstration, validation in a simulated environment, large-scale testing, and so on. For engineers and project managers, it is a useful tool to decide when a technology is still experimental, when it is ready for a field demonstration, or when it is finally reliable for commercial applications.

To concretely support these development phases, engineers and project managers also rely on digital tools capable of managing the complexity of industrial design. Solutions like ESAPRO, based on AutoCAD and BricsCAD, help to design, document, and verify industrial plants flexibly and reliably, reducing errors and work times along the path that takes a technology from the experimental phase to real operation.

The 9 levels of the TRL scale

Understanding where a technology stands along its development cycle is fundamental for making informed decisions, planning investments, and reducing risks. The TRL scale allows you to precisely identify the phase in which an innovation is located, and which steps remain to be taken to bring it to industrial application and the market.

Each Technology Readiness Level therefore has a precise meaning, linked to measurable and verifiable results. Here we analyze them one by one.

- TRL 1 – Basic observation

In this phase, the scientific principles that could underlie a future technology are identified. There is not yet a defined application idea, but only theoretical knowledge as a starting point.

- TRL 2 – Technological concept

Theoretical knowledge is translated into a proposed solution. It begins to outline how those principles can generate a technology, through conceptual models or preliminary schemes.

- TRL 3 – Experimental proof of concept

The hypothesis is tested with controlled experiments that demonstrate the feasibility of the principle. It is not yet a prototype, but a first experimental result that validates the underlying idea.

- TRL 4 – Laboratory verification

Here, a basic prototype is created and tested in the laboratory. The main functionalities are present, even if the technology is far from being optimized or ready for the real environment.

- TRL 5 – Testing in a simulated environment

The prototype is adapted to function in an environment that replicates, at least in part, real operating conditions. This serves to help us to understand if the system withstands constraints closer to reality compared to the laboratory.

- TRL 6 – Demonstration in an industrial environment

The process moves to an advanced prototype, tested in a real or highly representative context. The system undergoes field tests to verify compatibility and robustness in concrete operating conditions.

- TRL 7 – Demonstration of the complete system on a reduced scale

The system is complete and operational and is used on a limited scale, directly in the target environment. The goal is to refine performance and collect data on effectiveness and reliability.

- TRL 8 – Final system in full operation

The technology has now reached its final configuration and is used operationally on a large scale, demonstrating solidity and the ability to integrate into industrial processes.

- TRL 9 – Operational technology ready for the market

The last TRL level certifies that the technology is ready for the market, fully validated and already distributed or installed. It is no longer a prototype, but a consolidated and available solution.

This overview of the Technology Readiness Level TRL clarifies how to assess the maturity of a technology along its path to the market. A key point to clarify is: what is the difference between TRL 5 and TRL 6? The distinction lies in the testing environment: at level 5, the technology is validated in simulated conditions, while at level 6 it is demonstrated in a real or closely representative operational environment, marking a decisive step towards industrial application.

Why is it important to measure the Technology Readiness Level (TRL)?

Assessing the Technology Readiness Level is not just a technical exercise, but a strategic choice for those who develop, finance, or adopt new technologies. Knowing where a solution stands along the technology maturity scale allows you to reduce risks and allocate resources more effectively.

First, the TRL levels helps to measure the degree of innovation: it allows you to understand whether a technology is still in the experimental phase, ready to be tested in the field, or already mature for the market. This awareness is crucial for deciding where to focus development efforts and which aspects still need to be refined.

For those who need to make investment decisions, the Technology Readiness Levels are a useful tool for assessing technical risk and estimating potential economic return. Investing in a technology with a low level involves longer timelines and greater uncertainty, while betting on solutions with a high TRL scale means financing a product that is already reliable and close to commercialization.

Companies can also use the Technology Readiness Level to plan internal development, realistically assigning budgets and timelines to projects, monitoring progress along the life cycle, and identifying potential technical obstacles in advance.

Finally, it is also a valuable metric for organizations aiming to consolidate their technological maturity. In the most advanced industrial contexts, such as Industry 4.0, knowing exactly at what level each new technology is positioned makes it possible to build coherent digital strategies, improve operational efficiency, and strengthen competitiveness in the market.

The Technology Readiness Level, therefore, makes it possible to make informed, rational, and growth-oriented decisions, transforming innovation management into a structured and measurable process