Industrial desalination plants represent an optimal solution for obtaining fresh water from marine or brackish resources, meeting the needs of production sectors increasingly oriented towards sustainability and the optimization of water resources. There are several industrial desalination plants that allow the separation of salt from water, ensuring a high quality of the final result.

In particular, reverse osmosis and thermal desalination plants are among the most widespread in the industrial field today, thanks to their ability to adapt to different treatment volumes and various levels of salinity.

In this in-depth analysis, we will examine in detail what are industrial desalination plants, the main differences between the available technologies, and the advantages they can offer for the design and management of an efficient and reliable industrial plant.

What are industrial desalination plants

Industrial desalination plants are systems designed to remove salts and impurities present in seawater or brackish water, making them suitable for various productive uses. Unlike small plants intended for domestic or municipal applications, industrial solutions are designed to handle large water flows (between 2,000 and 12,000 cubic meters per day) with continuous operation and high-quality standards.

Those involved in the design of industrial desalination plants can rely on professional tools such as ESApro 3D Piping, which allow modeling not only the piping lines but also the pipe supports, supporting structures, and automatically generating detailed construction drawings and complete isometric sketches. Essential functionalities to precisely meet the technical requirements requested by the client and efficiently integrate this type of plant into the most complex industrial projects.

The adoption of seawater desalination plants is particularly strategic in sectors such as the energy, chemical, pharmaceutical, and food industries, where secure and constant water supply is essential to ensure the continuity of activities. The choice of the most suitable technology depends on various factors, including the quality of the raw water, the intended use of the treated water, and long-term management costs.

Desalination, in fact, allows transforming an abundant resource like seawater, which covers over 70% of the Earth’s surface and constitutes about 97% of the world’s water reserves, into fresh water usable for industrial and civil purposes. In today’s world, where the availability of drinking water is increasingly at risk, especially in areas subject to drought or desertification, industrial desalination plants offer a concrete response to the problem of water scarcity.

The industrial desalination process can occur through physical or chemical methods, which separate water from dissolved solids using principles such as pressure difference or state change.

Thanks to these technologies, it is possible to increase sources of fresh water supply, improve the resilience of coastal areas, and reduce dependence on water resources imported from other regions. The use of seawater desalination plants, like industrial wastewater treatment plants, allows responsible management of local water resources, ensuring continuity in the supply of high-quality water even in critical climatic conditions.

Reverse osmosis and thermal desalination plants

Among the main industrial desalination technologies, reverse osmosis systems and thermal desalination plants represent the two main solutions adopted on a large scale. Both are based on established physical principles and can offer high performance, but they differ in operating modes, areas of use, and energy requirements.

The choice between a reverse osmosis plant or a thermal system depends on various factors, such as the salinity level of the water to be treated, the availability of energy, and the required production volume.

Therefore, the main types of industrial desalination plants are:

- Reverse osmosis desalination plants (RO)

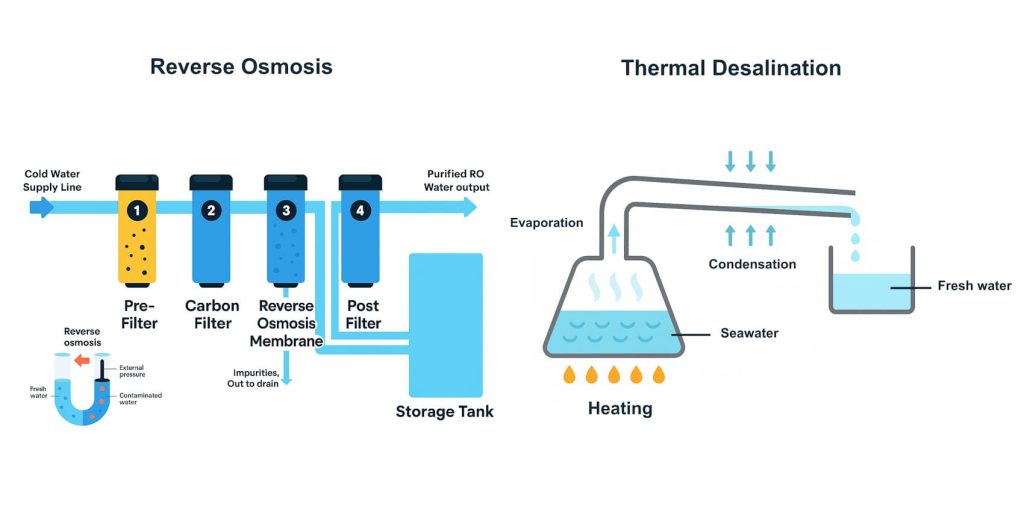

The operation of a reverse osmosis desalination plant involves several stages. During pre-treatment, raw water is subjected to thorough filtration and enriched with specific chemical agents to prevent scaling and microorganism growth. Subsequently, a high-pressure pump pushes the water against a series of semi-permeable membranes, adapted according to the type of water to be treated, whether brackish or marine. In the separation phase, only pure water molecules can pass through the membranes, while salts and impurities are blocked. Finally, post-treatment involves the remineralization of the filtered water to make it compliant with the standards required for the intended use, whether civil or industrial.

- Thermal desalination plants (TD)

Thermal desalination plants exploit the principle of water evaporation at high temperatures to separate it from dissolved salts. Among the most established technologies are the MSF (Multi-Stage Flash) and MED (Multi-Effect Distillation) processes. Industrial thermal desalination plants are ideal for handling large volumes of high-salinity water and are often associated with cogeneration plants, where waste heat can be reused, reducing energy consumption. This solution is particularly suitable for large-scale installations capable of treating tens of thousands of cubic meters per day.

- Hybrid Systems

In some specific contexts, hybrid solutions combining thermal and reverse osmosis technologies are used. This integration allows optimizing energy efficiency and reducing the production costs of fresh water, adapting flexibly to operational conditions and design requirements.

After analyzing the main characteristics of reverse osmosis and thermal desalination plants, it is possible to better understand in which contexts it is advisable to choose one technology over the other. Factors such as the salinity level of the water to be treated, energy availability, required volume, and environmental conditions influence the choice of the most suitable solution for each plant.