During the design of an industrial plant, choosing the right material is essential to ensure functionality, durability, and safety. Among the most common solutions, AISI steel is a constant reference due to its precise and internationally shared classification.

In this article, we will delve into the characteristics of the most commonly used stainless steels, analyzing differences, uses, and criteria for recognizing them. The goal is to provide a practical guide for those involved in design, production, or material selection, with a focus on the strengths of AISI 304 vs 316 stainless steel.

In fact, understanding the difference between AISI 304 and AISI 316 stainless steel is crucial to optimize every phase of the process, from CAD design to the realization of the finished product. The AISI classification allows precise orientation among the different alloys thanks to a reliable and universally adopted numerical system. Therefore, knowing the characteristics of AISI 304 steel in detail allows for targeted selection based on the usage environment and the required technical specifications.

The acronym AISI (American Iron and Steel Institute) is not just an acronym but a quality standard. Through specific numbering, such as the 3XX series, austenitic steels are identified, i.e., those containing chromium and nickel. Within this family, we find the AISI 304 and AISI 316 steel alloys, each with unique uses and properties.

For a broader comparison of materials used in the mechanical industry, it is also useful to consider the mechanical characteristics of ASTM A105 steel, another widely used alloy in structural and plant engineering.

AISI 304 composition and key characteristics

In this context, it is important to highlight that AISI steels are mainly divided into four large families: carbon steels, low-alloy steels, high-alloy steels, and stainless steels. It is in this last category that AISI 304 and 316 stainless steels are found, appreciated for their corrosion resistance and excellent performance in critical areas such as the food, chemical, and nautical industries.

AISI 304 steel is one of the most versatile and widely used alloys in the world of industrial design, thanks to the balanced combination of strength, ductility, and workability. Belonging to the family of austenitic steels, this material is also known as “18/8 steel” due to its typical composition: 18% chromium and 8% nickel.

The presence of chromium is fundamental: it allows the formation of a stable and invisible surface oxide layer that protects the metal from corrosion. This layer, known for its self-healing ability, ensures protection even in the case of small scratches or abrasions, making AISI 304 stainless steel ideal for environments exposed to moderate corrosive agents.

The nickel content, on the other hand, significantly improves ductility and weldability, contributing to the good workability of the material. These properties make AISI 304 stainless steel perfect for the creation of complex and precision elements, especially when forming and bending are required without compromising mechanical strength.

Among the main characteristics of AISI 304 steel, the following stand out:

- High resistance to oxidation and light chemical agents.

- Excellent weldability, even without subsequent heat treatments.

- Good mechanical resistance at both high and low temperatures.

- Easily polishable surface, for aesthetic and hygienic purposes.

The specific weight of AISI 304 is approximately 7.9 g/cm³, a relevant figure in structural evaluations and CAD/CAM design. Knowing this value helps calculate masses, forces, and loads in the initial engineering phases.

For this reason, these materials are included in the libraries of the main software for 3D modeling of industrial plants. Among these, ESAPRO 3D Piping represents a complete solution for industrial design: it includes a wide range of components and pipes already coded according to the most common standards, facilitating the selection and standardization of materials from the early stages of the project.

From an application point of view, this alloy is used in many fields: food processing plants, architectural cladding, tanks, heat exchangers, and automotive components. It is considered a standard in the design of elements that require high performance without sacrificing cost-effectiveness and production simplicity.

Although there are other more performing alloys in particularly aggressive environments, AISI 304 steel is a reliable choice for most industrial and civil applications. It is important to note that the “304” code identifies not only the chemical composition but also a set of properties validated by experience and international standards.

In the AISI 304 vs 316 comparison, the differences mainly emerge in terms of resistance to marine corrosion or exposure to chlorides. However, the former remains a reference material for those seeking a balance between performance, availability, and costs.

Differences between AISI 304 and AISI 316 steel

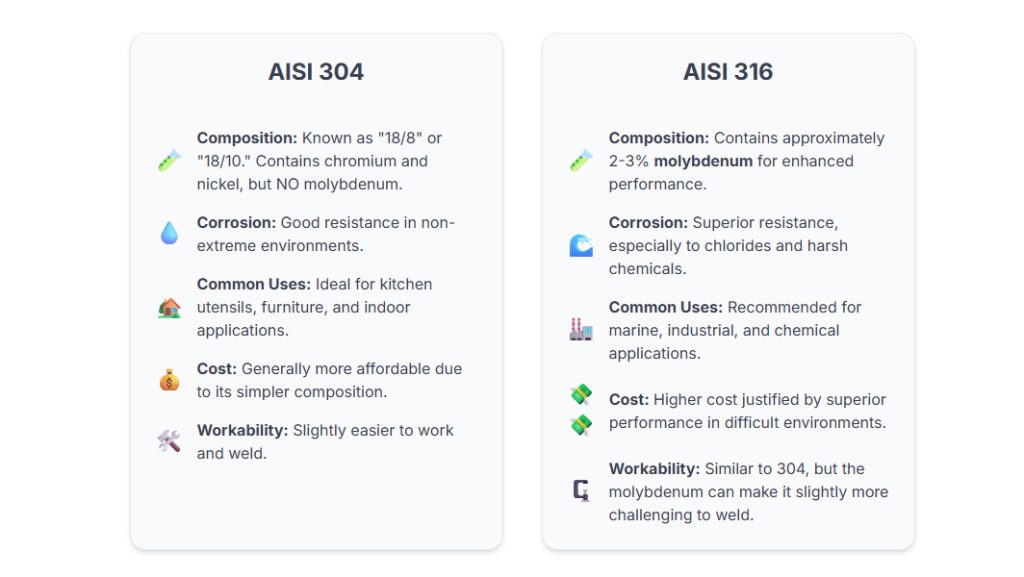

Although both belong to the family of austenitic stainless steels, AISI 304 and 316 steel differ in some chemical and performance characteristics that make them suitable for different uses. Understanding the differences between AISI 304 and AISI 316 steel is essential to select the most suitable material based on the operational context.

The key point that separates these two grades of stainless steel is the presence of molybdenum in 316 steel. This alloy contains about 2-3% molybdenum, an element that significantly enhances corrosion resistance, particularly in environments containing chlorides, such as brackish water or marine atmosphere. This addition makes this alloy preferable for external applications, aggressive chemical environments, industrial or naval plants.

AISI 304 stainless steel, on the other hand, does not contain molybdenum: as mentioned earlier, it is commonly known as “18/10” or “18/8” due to its typical composition of chromium and nickel. It is widely used to produce kitchen utensils, furniture components, and sanitary systems, thanks to its excellent balance between cost, ease of processing, and corrosion resistance in non-extreme environments.

From a practical point of view, therefore, the choice between the two depends on the intended use:

- AISI 304: ideal for indoor or non-particularly aggressive environments, where prolonged exposure to salts or strong chemical agents is not expected.

- AISI 316: Recommended for marine environments, chemical industries, or applications where stainless steel is subjected to particularly corrosive conditions.

The differences between AISI 304 and 316 steel are not limited to chemical resistance. 316 generally has a higher cost, justified by superior performance in difficult environmental conditions. Workability is also similar, but 304, free of molybdenum, tends to be slightly easier to work and weld, while still maintaining excellent mechanical resistance.

Although they are visually indistinguishable, there are specific tools to determine whether an alloy is AISI 304 or 316 stainless steel. The use of chemical reagents can reveal the presence of molybdenum, while more advanced analyses with spectrometers can precisely determine the alloy’s composition.

Knowing these differences in depth is essential to optimize industrial projects and ensure durability and performance over time.