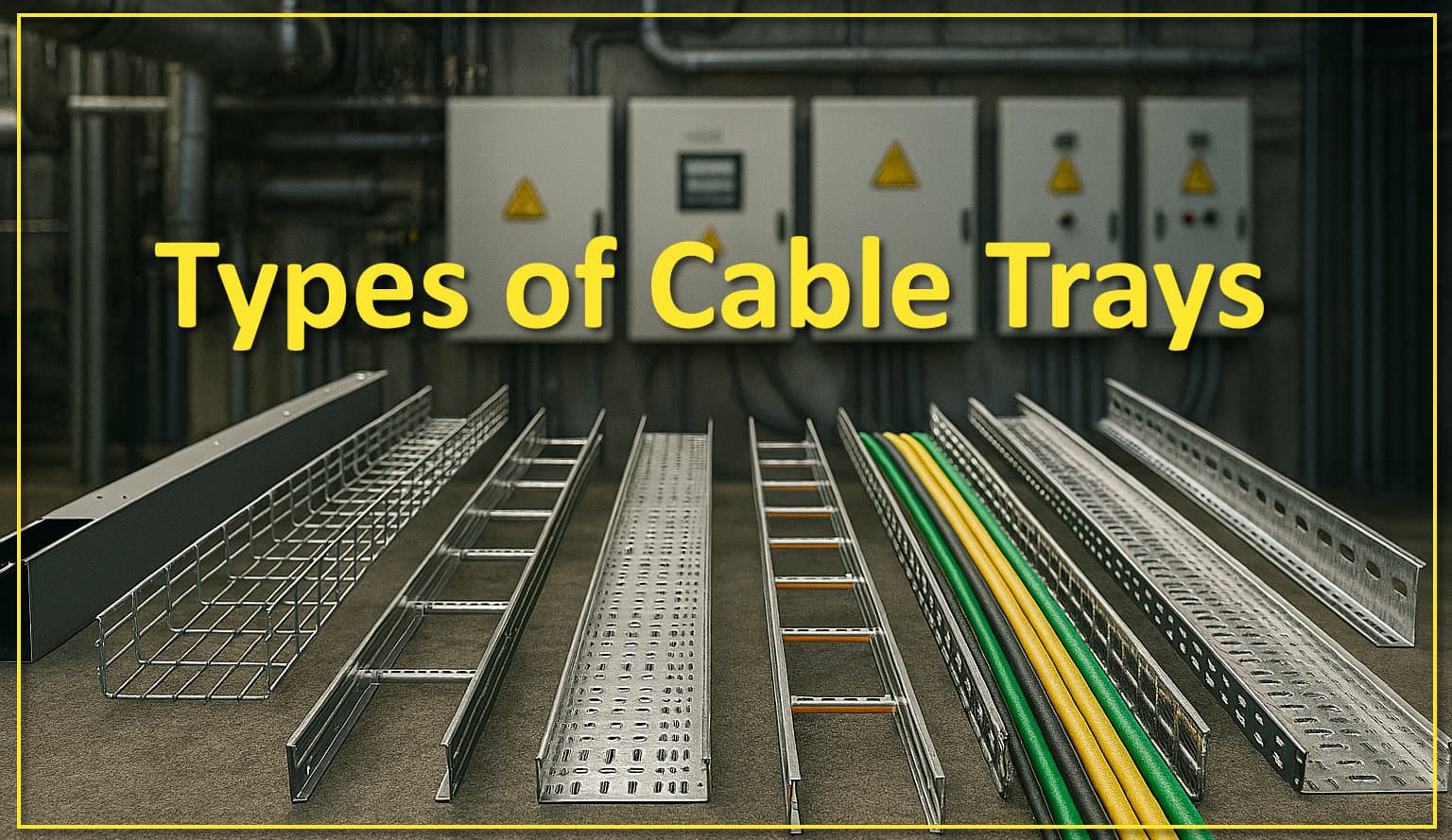

Industrial electric cable trays, are fundamental to ensuring a safe and organized installation of electrical systems. These support systems are used to organize electrical cables inside industrial, commercial, and residential buildings and play an important role in making sure cables are protected, easily accessible for maintenance, and able to withstand mechanical stress during operation.

Industrial electrical cable trays not only contribute to the safety of the system but also facilitate proper dissipation of heat generated by the cables themselves, a crucial aspect in high-energy environments.

The evolution of wiring systems has made industrial electric cable trays increasingly sophisticated solutions, capable of meeting the needs of complex spaces and high-density cable systems. From standardized dimensions to the choice of materials from which they are made, every detail is designed to optimize efficiency and ensure adequate protection of the electrical system.

In this article, we will explore electrical cable tray types and how they operate, to understand their essential role in modern electrical system design.

What are industrial electric cable trays and what are they used for

As previously mentioned, industrial electric cable trays are support systems designed to host and protect cables within a facility, ensuring order and safety during installation and maintenance.

These systems allow for safe and organized cable management, minimizing clutter and making maintenance operations easier. Electric cable trays, often made from robust materials such as galvanized or stainless steel, are ideal for industrial environments where durability and protection against corrosion are essential.

In fact, one of the main functions is to protect cables from physical damage, such as impacts or compression, but also from adverse environmental factors, like humidity or exposure to chemicals. At the same time, they provide a clear and easily accessible pathway for cable inspection and replacement, simplifying maintenance.

Proper design of electrical cable trays also enables effective heat dissipation, reducing the risk of overheating and ensuring safe and reliable operation over time. In complex contexts like industrial plants, data centers, and commercial structures, this electrical infrastructure represents an economical and practical solution, capable of efficiently and safely managing large quantities of cables.

For those seeking an advanced solution for the design and management of electrical cable trays and conduits, ESAPRO Cable Trays offers advanced 3D modeling that enables detailed design of cable routes and accessory metal structures, optimizing the plant layout and ensuring high efficiency in resource management.

Thanks to an extensive dimensional catalog and the ability to automatically generate bills of materials, the cable tray design software is an essential resource for improving their placement within the system and checking for possible interferences.

Industrial electrical cable tray types

This electrical infrastructure is available in several types, each designed to meet the specific needs of every system. Each cable tray, like the main types of electrical pipe conduits, offers unique advantages in terms of safety, efficiency, and ease of maintenance, making them essential to ensure the proper functioning of electrical systems.

Here is an overview of electrical cable tray types:

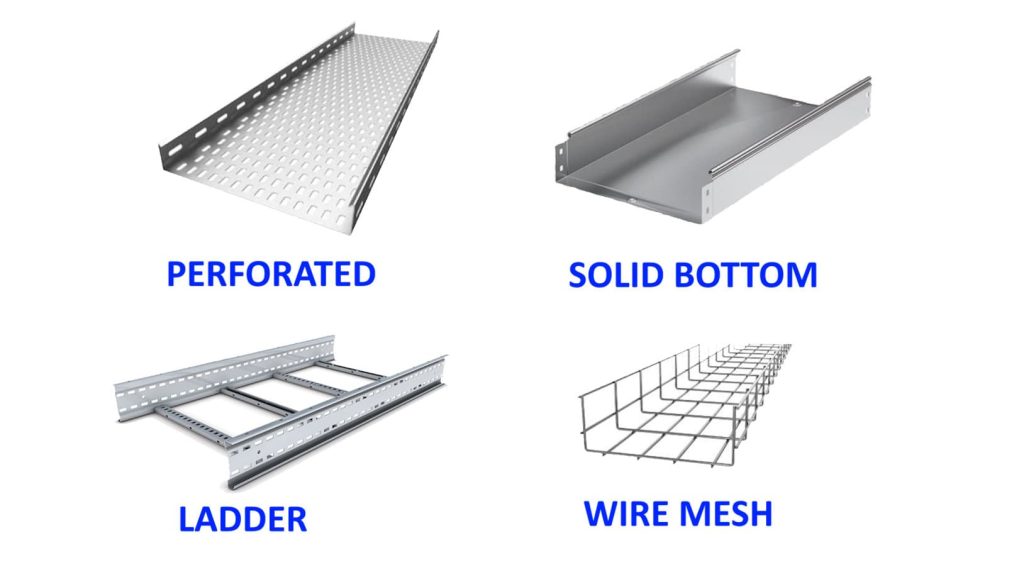

- Ladder cable tray. This type features a rung structure that enables effective cable management, facilitating ventilation and heat dissipation. Ideal for industrial installations and environments where cables are exposed to mechanical stress, it is a common choice for wind turbines, solar plants, data centers, and factories. Its simple structure allows for quick installations and easy maintenance interventions.

- Perforated cable tray. Characterized by a design with holes that allow optimal air circulation, this structure is perfect for applications where good ventilation is required, such as in industrial plants or data centers. Perforated trays protect cables from dust and contaminants, reducing the risk of overheating, and are suitable for complex installations thanks to their ease of customization.

- Solid bottom cable tray. With a continuous surface, this type offers protection against physical damage such as crushing and abrasion. It is particularly suitable in environments where shielding against electromagnetic interference is required, such as in data centers or healthcare facilities, ensuring both protection and reliability. Generally made of hot-dip galvanized steel or aluminum, its neat appearance makes it ideal for visible spaces, such as offices and commercial environments.

Each electrical cable tray type is designed to optimize cable management according to the specific needs of the environment and project, allowing for an efficient and safe configuration of the electrical system