Modern industry increasingly relies on non destructive testing (NDT) to ensure the safety, reliability, and longevity of materials and equipment used. These techniques allow for thorough inspections without compromising the integrity of the tested object, distinguishing them from traditional methods that require the destruction of the material.

The adoption of industrial non-destructive testing is crucial in numerous sectors, such as aerospace, automotive, energy, and construction industries, where safety and quality are of paramount importance. With the advancement of technologies, numerous tools and methodologies are now available, including ultrasonic non destructive testing, which provides highly accurate results.

These innovative methods are essential for effective risk management and maintaining high-quality standards: they ensure that components can withstand the stresses they are subjected to.

In this article, we will explore what non destructive testing is, the main differences with destructive testing, and some of the most used techniques in this field.

What is non destructive testing?

Non destructive testing (NDT) is a set of techniques used to examine the quality and integrity of components and materials without compromising their structure or functionality. These methods are designed to detect defects that might go unnoticed during production, such as microcracks, porosity, or signs of surface corrosion.

Unlike destructive testing, which requires damaging the sample to verify its characteristics, industrial non-destructive testing allows for accurate results without altering the tested material. The main goal of non-destructive test is to prevent long-term damage by promptly identifying potential issues that could compromise the safety and reliability of the examined component or structure.

As we will see, among the main non-destructive tests are the use of ultrasound, which allows probing the depth of materials, and X-rays, which enable visualization of the internal structure of components. Each NDT method is designed to meet specific needs, ensuring the effectiveness of the control based on the type of material and the type of defect to be identified.

Indeed, the ability to perform inspections without compromising the sample examined represents a fundamental advantage, especially in sectors where safety and reliability are indispensable, such as the aerospace, automotive, and infrastructure industries.

Industrial non-destructive testing on steel pipes, for example, plays a crucial role in nensuring the safety and quality of the finished product. Since the production of these pipes involves a series of complex stages, such as melting, rolling, and processing, it is essential to identify any defects that could compromise the material’s performance. These tests are particularly effective in detecting issues such as cracks, deformations, or inclusions, ensuring that steel pipes, such as those used for water-piping, are suitable for their intended use.

To further optimize the design of a plant, it is essential to use advanced software that allows for the creation of three-dimensional layouts of piping lines, respecting the technical specifications of the materials and the project’s requirements. Tools like ESAin’s piping software offer advanced features for creating accurate models of the piping, integrating detailed information about plant components, such as pipes, valves, and bends.

The software also allows for the automatic generation of material lists, organized by lines and areas of the plant, improving the efficiency of the design phase and reducing the risk of errors during the implementation of the industrial plant.

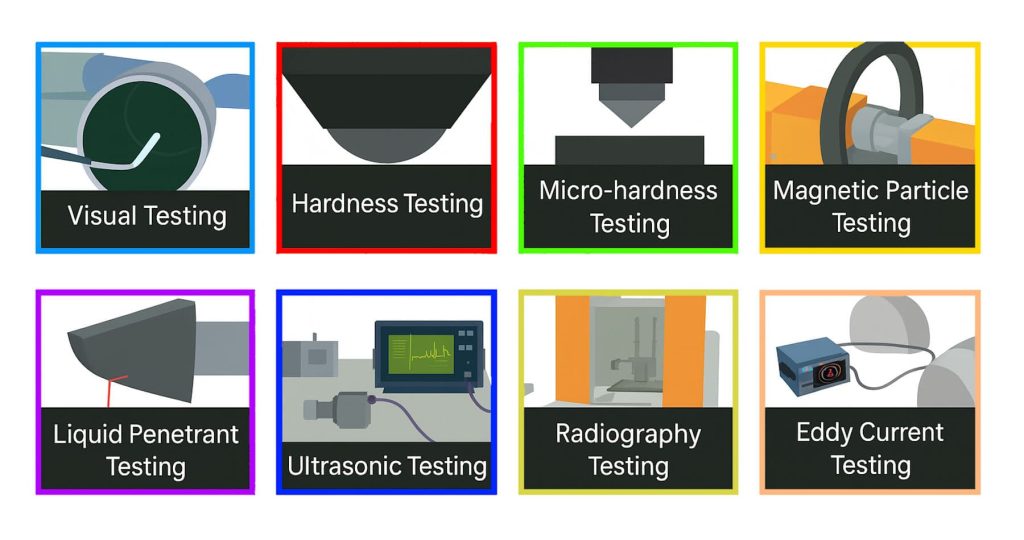

Non destructive testing methods

Industrial non destructive testing (NDT), thanks to its ability to identify issues invisible to the naked eye, allows for the prevention of failures and ensures the proper functioning of plants.

The UNI EN 12062 standard, for example, provides the general rules for the application of non destructive tests on welds, establishing the criteria to be followed to ensure that tests are carried out correctly and consistently. Added to these are UNI EN ISO 5817, which defines the acceptable quality levels for imperfections in welded joints, and UNI EN 3834, which provides the quality requirements for welding. These standards are fundamental for establishing operational standards and ensuring that inspections are carried out properly, maintaining high levels of safety and quality.

Non destructive testing techniques are numerous and are chosen based on the type of material, the nature of the defect to be detected, and the environment of use. In addition to the methods listed below, one of the fundamental complementary methods in these contexts is leak testing, which allows for the detection of any leaks in pipes without compromising their structural integrity.

Below is an overview of the main methods used:

- Visual testing. This is the simplest and most widespread technique. It involves observing the surface of the component, often with the help of tools such as magnifying glasses or cameras, to identify surface defects such as cracks, corrosion, or deformations.

- Ultrasonic testing. Used to evaluate the internal quality of the material, ultrasonic testing sends high-frequency sound waves that, reflecting from internal discontinuities, reveal the presence of defects such as cracks or inclusions. This method is particularly precise and suitable for thick materials

- Radiographic testing. It uses high-energy radiation (X-rays or γ-rays) to penetrate the material and produce images that highlight internal discontinuities. Radiographs allow for the examination of the internal structure of a component, revealing defects such as voids, inclusions, or defective welds.

- Infrared thermography. Using infrared radiation, it allows for the detection of discontinuities in the material by monitoring temperature variations caused by defects such as leaks or damage. It is very useful for large-scale inspections of industrial plants, such as electrical circuits or heat exchangers.

- Magnetic particle inspection. This method is used to detect surface or shallow defects in ferromagnetic materials. It is based on the generation of a magnetic flux that is interrupted at discontinuities, such as cracks or porosity.

- Liquid penetrant testing. Ideal for detecting surface defects, this technique exploits the principle of capillarity. A penetrant liquid is applied to the surface of the component and then revealed by a visual method. It is very useful for identifying cracks, porosity, and micro-defects.

- Eddy current testing. This technique uses electromagnetic fields to detect surface and subsurface defects. It is often used to inspect conductive materials and is applied to detect cracks or corrosion.

Each industrial non destructive testing method has specific advantages, depending on the type of plant or component to be examined. The combination of these techniques allows for a comprehensive and precise analysis of the components analyzed, thus ensuring the safety and efficiency of the industrial plant in the medium and long term.