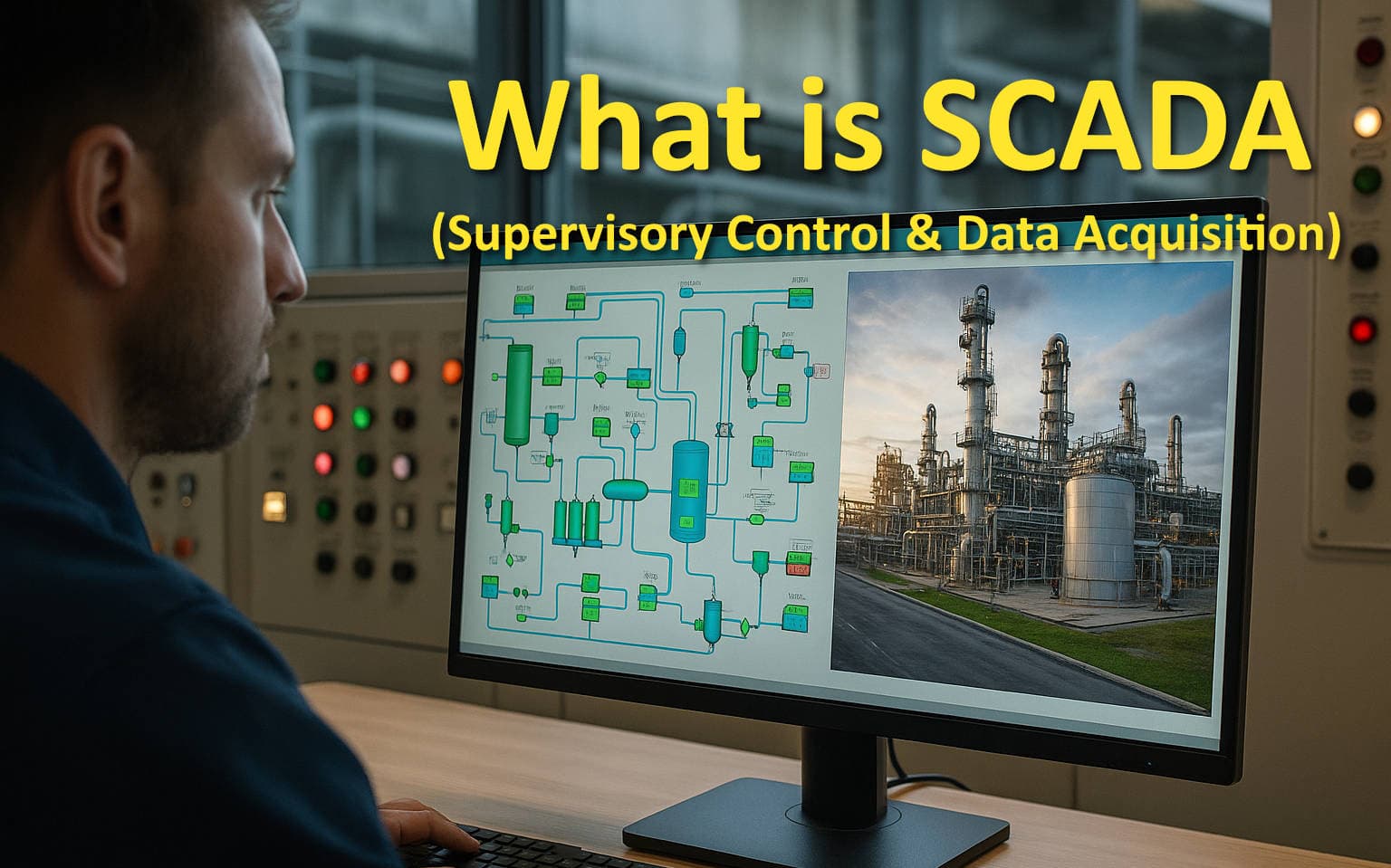

The SCADA system (Supervisory Control and Data Acquisition) is a technology that allows the monitoring and control of industrial processes, such as those used in production plants, infrastructure, and transportation. This industrial control system (ICS) represents the beating heart of numerous operations, offering the ability to collect and analyze data in real-time, optimize performance, and ensure a high level of security.

From managing electrical systems to water treatment operations, the SCADA system improves the efficiency and management of complex plants. The SCADA system integrates perfectly with the main software for industrial plant design, such as ESAPRO, which facilitates collaboration between process, plant, and electrical design, ensuring always updated and shared data. Thanks to an integrated database, all technical data is centralized and made accessible in real-time, ensuring interoperability with other software and improving the overall efficiency of the design process.

In this article, we will explore in detail what the SCADA system is, how it works, and its most relevant industrial applications. We will also delve into the differences between SCADA and HMI, two components that, although similar, respond to distinct needs.

What is SCADA system

As mentioned earlier, the SCADA system (Supervisory Control and Data Acquisition) is an advanced technological solution used for monitoring and controlling complex industrial processes. These systems, usually distributed and modular, allow the collection, processing, and visualization of data from production and infrastructure plants, even remotely. Their main objective is to optimize operational efficiency and profitability, providing operators with a real-time overview of the state of the plants.

Structurally, the Supervisory Control and Data Acquisition is based on a combination of software and hardware, which includes programmable logic controllers (PLC), remote terminal units (RTU), and a communication network that allows data exchange between the various components. These data are collected by sensors installed on the machinery and, through human-machine interfaces (HMI), operators can supervise and manage the plant’s operations.

The architecture of the SCADA system allows centralized management of information, simplifying the configuration of systems and their control. Although it was born more than fifty years ago, it continues to evolve, adapting to new technologies and the needs of a market oriented towards the use of Big Data in industrial design. Therefore, a SCADA system does not only collect data but uses it to optimize industrial processes, ensuring safety and improving productivity, thus becoming an indispensable resource for modern smart factories and complex industrial plants.

How does a SCADA system work?

The operation of a SCADA system is based on the collection and processing of data from sensors and field devices, which monitor and control various industrial processes.

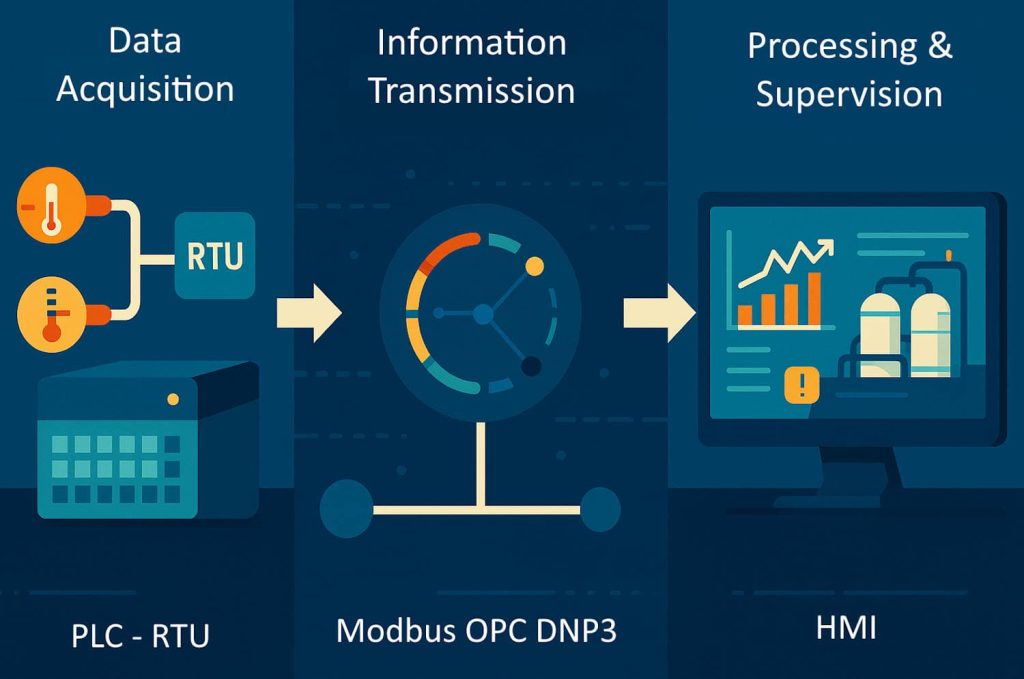

Its structure is designed to operate efficiently through three main phases:

- Data acquisition: Sensors connected to the equipment detect physical parameters such as temperature, pressure, flow, or voltage and convert them into electrical signals understandable by the system. These data are transmitted to peripheral devices, such as PLCs (programmable logic controllers) and RTUs (remote terminal units), which act as an interface between the process and supervision.

- Information transmission: Communication between the several components of the system takes place through a transmission network, which can use different communication protocols to ensure the security and reliability of information transfer (such as Modbus, OPC, DNP3).

- Processing and supervision: Once the data is collected, it is analyzed by supervision software that shows the information in real-time through human-machine interfaces (HMI). Operators, based on the displayed data, can intervene to adjust the process, activate alarms in case of anomalies, or make changes to optimize efficiency.

The heart of these control systems is precisely the ability to monitor and control complex processes, such as industrial ones, from a central and remote position. The different communication protocols, such as Modbus, OPC, DNP3, or IEC 60870-5, allow data transmission between various devices and enable the transformation of physical information into easily usable digital data.

Differences between SCADA, HMI, and DCS

Although SCADA and HMI systems are often considered synonymous, they actually represent two distinct components with precise functions within an industrial plant. Understanding the differences between SCADA, HMI, and DCS is essential to optimize automation and process control.

The HMI (Human-Machine Interface) is the interface that allows operators to interact directly with the system, transforming human commands into executable actions by the machines. Its main function is to display data and allow the input of commands for plant control.

On the contrary, the Supervisory Control and Data Acquisition is the system that collects data from field devices (such as sensors and PLCs), monitoring and supervising processes. Therefore, the HMI is the tool through which the operator interacts with SCADA, which provides support for data acquisition and processing. Finally, while the latter is typically used for monitoring and controlling distributed plants, the DCS (Distributed Control System) is designed to manage complex and large-scale industrial processes, such as those present in refining plants or power generation.

Unlike SCADA, which is based on a WAN (Wide Area Network) structure, DCS operates on LAN (Local Area Network) networks, with the aim of centrally and in real-time managing a wide range of data.

A DCS system stands out for the close integration between data acquisition and processing. In a DCS, control and supervision devices are more interconnected, with processing capacity distributed among various modules. This allows tighter and more responsive process control, offering more flexible supervision and less dependent on direct communication between components.

Finally, while SCADA focuses on real-time data supervision and acquisition, DCS is more oriented towards decentralized control of highly complex processes. The choice between the two depends on the specific needs of each plant, including factors such as system distribution, scalability, and the complexity of the required control.

Industrial applications of the SCADA system

SCADA systems, originally developed for industrial automation, are now fundamental in a wide range of sectors. The versatility of these systems makes them indispensable not only in manufacturing but also in many areas related to public services and infrastructure management.

The industrial applications of the SCADA system are numerous and include, for example:

- Manufacturing industry: where it is used to monitor quality and optimize production processes in various sectors, such as plastics, wood, ceramics, and food. For example, in the food sector, it ensures the control of production and preservation processes, ensuring product quality and safety.

- Public network control: it is widely used for monitoring public utility networks, such as electrical, water, or railway networks. Additionally, it finds application in building automation, for the management and control of heating, ventilation, and air conditioning systems in buildings.

- Healthcare and environmental sector: In hospitals, it is used for the control of local and remote equipment, such as those for the preservation of organic materials. Additionally, in the environmental field, it is employed to monitor and reduce pollutant emissions and ensure compliance with environmental regulations.

Thanks to its ability to integrate with various devices and technologies, the SCADA system is a valuable resource for ensuring efficiency, safety, and compliance with current regulations in a wide range of industrial and infrastructural applications.